There are those who are thinkers and others who are doers. When the two types of people come together to collaborate on an idea, the end result typically requires a prototype. Prototypes, or models made for testing products, can be created in a wide variety of ways. Rapid prototyping, however, is a relatively recent industry buzzword.

What is Rapid Prototyping?

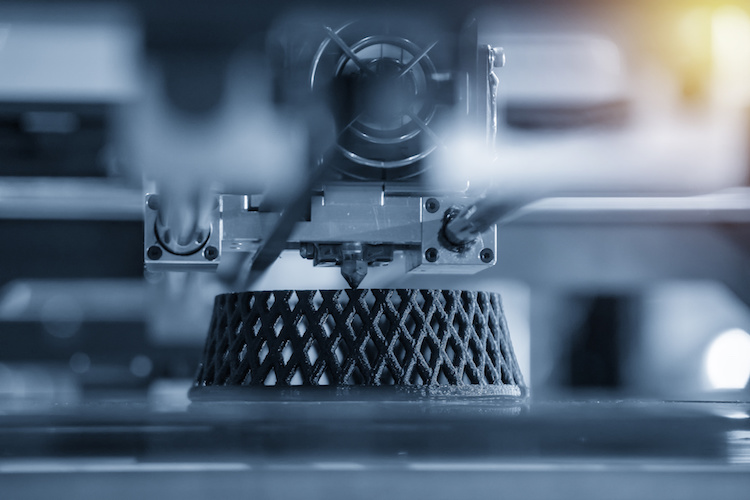

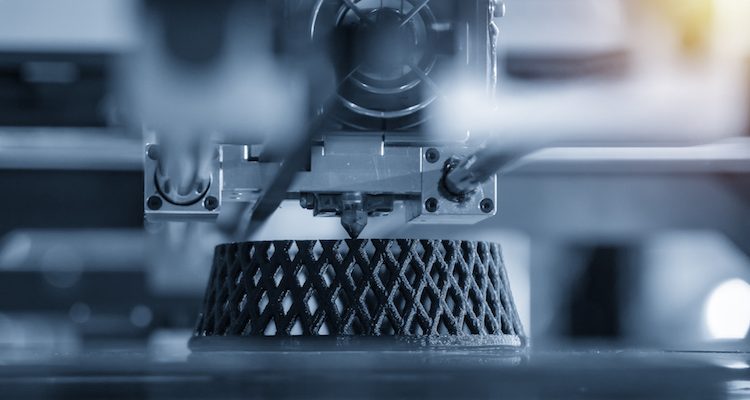

With the help of 3D computer-aided design, rapid prototyping broadly means the modern process of using computerized manufacturing techniques to quickly produce products that can be tested before bringing them to market. Prior to the computer age, prototypes were made using laborious techniques that included a significant amount of tedious hand work – often including tasks such as machining, sawing, filing, sanding, smoothing, and painting.

Today, many finished prototypes can be 3D printed or machined using subtractive rapid machining technologies. Many prototypes require complex multi-component assemblies, wherein each individual piece must be produced and then assembled. Especially when dealing with multi-component assemblies, the accuracy, or tolerance, of each individual component becomes crucial, so that each component works together with the others as desired.

Low vs. High-Fidelity

Depending on how close to the designed dimensions the finished component needs to be, a rapid prototype can be grouped as low or high-fidelity. A low-fidelity prototype is not as accurate, but it may suffice as a less-expensive, first-pass test, in order to give others the chance to visualize the concept. A high-fidelity, or tight-tolerance, prototype is basically a working version of the final product.

How Does it Impact My Business?

In order to compete in any industry, it’s crucial that the ideas never stop flowing and new products continue to be generated. Essentially, it’s the speed of rapid prototyping that will help your business keep up with the rest of the world. Imagine being able to think of a concept, design it, and have a prototype by the end of the day. You could then test your product and immediately start fixing its flaws or market it.

Pitfalls of Rapid Prototyping

While the technologies of rapid prototyping have changed the manufacturing industry in many wonderful ways, savvy buyers should realize that just because something can be designed for 3D printing or subtractive rapid machining, it doesn’t mean the design is what will work for the market-ready product. Why? 3D printers can produce things one at a time that are very costly, or even near-impossible to make in higher volumes. Internal holes, under-drafted areas, and complex internal corners can be difficult to mold or machine in high-speed applications. If a prototype is designed without proper forethought, it can mean costly redesigns and delays down the road, just when a company is getting ready to start producing higher volumes.

Why Should You Hire Custom Technologies?

Custom Technologies are engineering and manufacturing specialists that create success for their clients by providing holistic product development, manufacturing, and business services. One of our many areas of expertise is prototyping. There are no appearance models here, as we make fully functioning, testable, and manufacturable prototypes. And, we look ahead together with our clients – we can tell you at the prototyping stage how to optimize your product’s design now, in the early stages, ensuring efficient manufacturability later. We don’t just make prototypes and throw them over the wall to someone else for the manufacturing stage. We know manufacturing, we do manufacturing, and we’ll stick with you every step of the way.

Contact us today or visit customtechnologies.com to learn more.