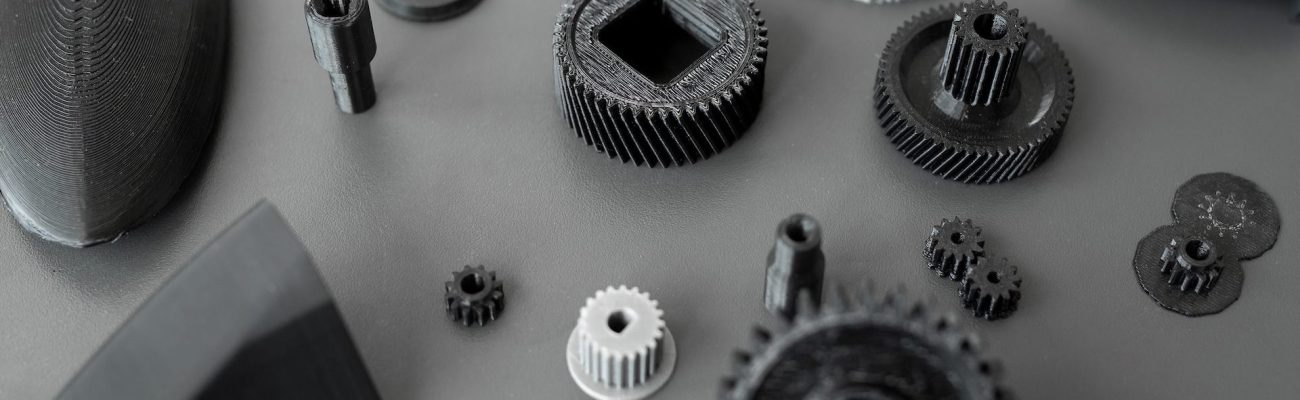

Here’s a wild guess – you’ve tried 3D printing individual pieces of your multi-component prototype but they don’t quite fit together. While the design may look perfect in a solid-model CAD file, there are still other factors to consider before hitting the print button. Custom Technologies specifically recommends that you consider dimensional tolerancing (how much inaccuracy you are able to tolerate in a given dimension) in product design.

Dimensional Imprecision

3D printing can be very imprecise dimensionally. In fact, all production processes are imprecise, with some being more so than others. The “dimensional tolerance” of 3D printing is notoriously poor, so that’s where it comes into play in product design. Also, it needs to be done sooner rather than later during the design process. If tolerancing is not specified carefully enough when launching a product for actual production volumes, multiple components will likely not fit together as intended.

Add Tolerances for Each Component

Few people realize that solid-model CAD design files don’t include tolerancing at all. These details must be added to each individual component using careful engineering-detail work, so that the real manufactured parts fit together as intended. For example, if we design a simple two-piece assembly using a solid-model CAD software and only draw it for 3D printing, we simply just “get what we get” for each individual component’s accuracy when it prints. The accuracy is only a result of the printer’s quality.

More Than Just a Printing Problem

You might then ask, “Can’t we just get a very accurate printer and solve our problem?” While it would certainly help, that’s not all there is to designing multi-component products. Ask yourself the following:

- Are the different parts of the assembly supposed to fit together tightly or loosely?

- Should one part slip smoothly back and forth along the second part, or should they be so tightly aligned that we want them to be pounded together with force?

If one part must fit inside another part, then they each must be designed so that (at the very least) the outside part is never smaller than the inside part. There is a real art to specifying tolerancing properly.

Trust in Hiring a Professional

There’s always a strong desire for those who like to use their hands to “do it yourself.” Being a team of skilled engineers, Custom Technologies fully understands that inclination. At the same time, however, there’s a time and a place to hire a professional who can ensure the most accurate results in a cost-effective manner. Designing a real, working product using 3D printing is more complicated than you may think – there are other considerations such as size, thickness, strength, shrinkage, shatter-resistance, and clearance. If these factors are not accounted for early on, your prototype won’t live up to your expectations.

Also, note that 3D printing is not the only route to take. That’s why we’ll work with you to decide what type of manufacturing your product needs. Our goal, when it comes to all aspects of manufacturing, is that you will:

- Lower your cost by hiring one party to get your product to market

- Save time as every step is handled in-house

- Streamline communication by only having to maintain one point of reliable contact

Trust in Custom Technologies to deliver a multi-component prototype that’s designed for manufacturability from day one. Contact us today or visit customtechnologies.com.