Outsource your new or existing manufacturing, precision

machining, and fabrication projects to Custom Technologies!

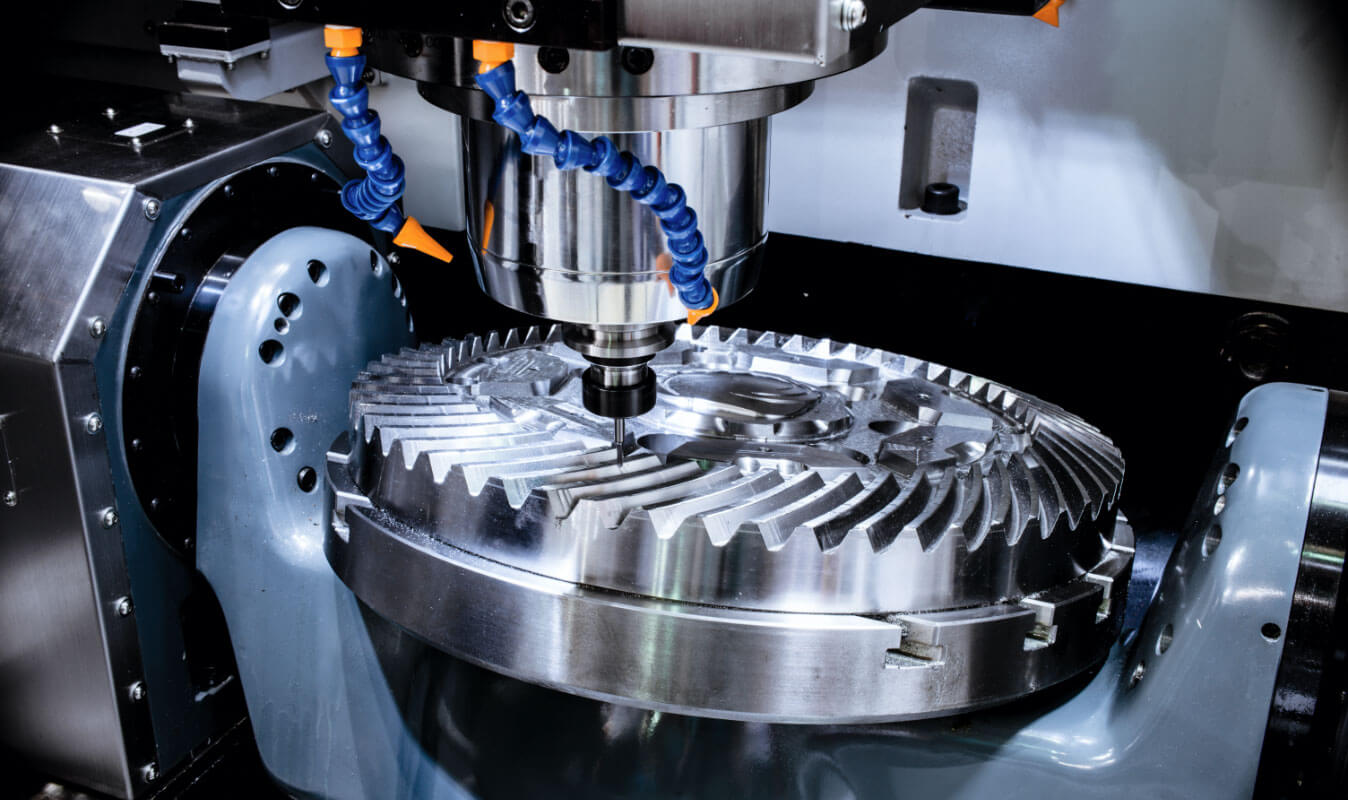

Custom Technologies is your on-site, one-stop-shop for all of your precision machining and fabrication needs. We work alongside you as a team and strive to completely understand your products so that we can help you reduce cost, increase quality, and produce your products properly for their intended function.

Custom fixtures are designed and implemented for each individual project to ensure repeatability, reliability, and efficiency during each individual operation.

Our experts are versatile and experienced working with a variety of industries, designing, machining, and fabricating high-quality products with extreme precision and to your exact specifications. Send us your CAD drawings, sketches, or samples and we’ll bring your project to life.

As part of our top-level involvement with our customers, we also provide a manufacturing analysis of how parts might be cost-reduced or how they may be redesigned for better overall functionality. If certain technical features are difficult to machine, you can count on us to make recommendations on how to modify them to the benefit of your overall product, costing you less in the end.

| Machine | Specifications | Capabilities |

|---|---|---|

| Mazak VTC-20B | 20" x 40" x 20" travel, 24 tool magazine (Capable of machining parts larger than travel dimensions due to stationary table) | Vertical CNC Milling Center with Pallet Changing system that allows for quick work piece changes and efficient fixturing. |

| Mazak Quick Turn Nexus 200-II MSY | 14" Maximum Machining Diameter, 22" Travel in Z, 12 Tool Magazine | Multi-axis Turning Center with live tooling and sub-spindle allows for simultaneous turning and milling without extra set-ups while holding tight tolerances. Integrated bar feeder allows for continuous operation. |

| Roland MDX-540 | 15.7" x 19.6" x 6.1" travel, with 4th-Axis rotary turntable | "Subtractive Manufacturing" milling machine allows for quick and easy prototype creation. Able to create molds and other 3D parts direct from solid file, similar to a 3D printer. This machine is also perfect for any engraving applications. |

| Tormach CNC-770 | 8" x 26" x 14" travel | CNC Mill with high-speed spindle, perfect for prototype and short-run parts. |

| Mazak Quick Turn 6T | 5.1" maximum machining diameter, 7.87" travel in Z, 8 tool magazine | CNC lathe for a wide variety of turned-part applications. |

| ACRA Manual Mill | 18" x 36" x 20" travel | Accurate milling for repair, one-off, and prototype parts. |

| Various Support Equipment | Various traditional machining, automation, and prototyping support equipment, e.g. cutoff saws, presses, ultrasonic parts cleaner, media tumbler, tapping stations, quality control equipment (microscope, surface table, gauges, calibration pins and blocks, etc.). | |

| Welding, Small Fabrication, and other Finishing Equipment | Small fabrication, sand blasting, grinding, and polishing in-house. We also have reliable partnered sources for heat treat, anodizing and other specialized paints and coatings. | |

| Low-pressure Injection Molding System | Custom Technologies proprietary system | In-house creation of molds and injection molding with a fast turn around time. Various materials both rigid and flexible. Ideal for prototyping and short runs. |

| Formlabs Form1+ SLA 3-D Printer | 25 micron resolution | Rapid prototyping from a solid model file. Maximum build area 6.5" x 4.9" x 4.9" |

| Boss Laser LS-2436 Industrial Laser Cutter/Engraver | Maximum work area 24" x 36". Cuts up to 3/4" thickness, depending on material. | Cutting, etching, and engraving for a wide spectrum of industrial and consumer applications. |

Contact us today at sales@customtechnologies.com to schedule your free consultation to discuss a custom solution tailored to your project’s needs!